Amid the joyful atmosphere of the Christmas season, cocoa powder production and the chocolate industry are experiencing unprecedented prosperity. As a beloved symbol of Christmas celebrations, the market demand for chocolate shows significant growth during this special period. The air jet mill, with its unique technical characteristics, has become essential in the fine processing of cocoa powder. It’s bringing new opportunities for improving the quality of chocolate.

I. Working principle of air jet mill

1.1 Basic principles of jet mill

As an advanced ultra-fine grinding equipment, the principle of the jet mill is to use high-speed airflow as power. When high-pressure compressed air is injected into the crushing chamber at a very high speed, the material particles are instantly in a state of high-speed motion. In this violent dynamic environment, frequent and intense impact collisions occur between material particles and between particles and the wall of the crushing chamber. These interacting forces work together to gradually break up and refine the material particles, ultimately reaching the desired particle size range. Compared with traditional mechanical grinding, this grinding method has unique advantages. It can perform well in avoiding excessive heating of materials and reducing the mixing of impurities, laying a solid foundation for the high-quality production of cocoa powder.

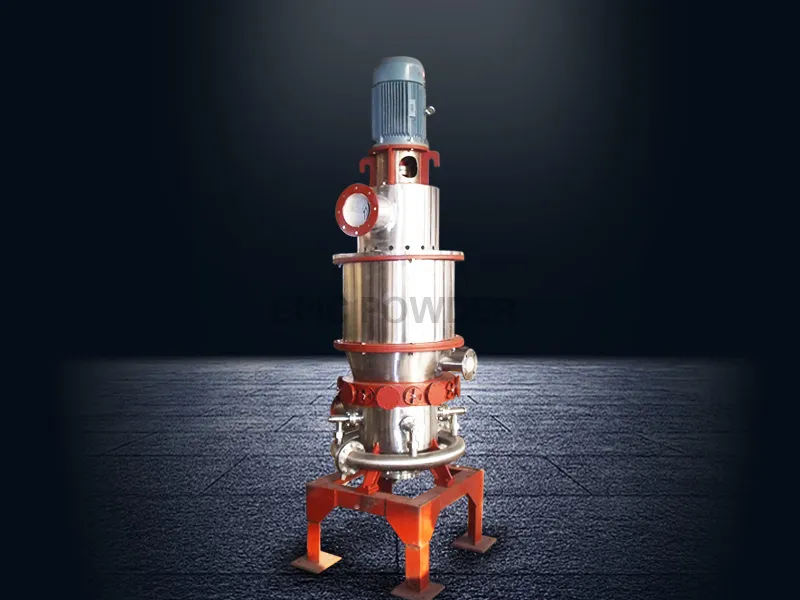

1.2 Working mechanism of fluidized bed jet mill

The fluidized bed jet mill integrates multiple advanced technologies, exhibiting exceptional crushing performance. During operation, compressed air is first accelerated through a specially designed nozzle to form a supersonic airflow. As this powerful airflow enters the crushing chamber, the materials inside appear to be fluidized, moving freely and rapidly in the airflow, almost as if they are endowed with lively vitality. At this point, the material particles violently collide and rub against each other under the influence of the high-speed airflow, completing the crushing process.

Simultaneously, the classifying device inside the crushing chamber acts as an accurate referee. Based on the pre-set particle size requirements, the fine powder that meets these criteria is promptly screened out and transported to the collection system. Meanwhile, the coarse particles that do not meet the particle size standards are retained in the chamber. These particles continue to undergo cyclic crushing until they achieve the desired fineness. The entire process is carried out in an orderly manner under the precise monitoring and control of the automatic system, ensuring the efficiency, stability, and consistency of cocoa powder production—much like the Christmas elves carefully crafting each gift.

II. Analysis of the application of air jet mill in producing cocoa powder

2.1 The process of air jet mill crushing cocoa beans

When the pre-treated cocoa beans enter the air jet mill, a wonderful journey of the microscopic world begins. Different types of air jet mills provide a variety of ways to crush cocoa beans. For example, the fluidized bed air jet mill uses its efficient fluidized state crushing mode to quickly crush the cocoa bean particles under the high-speed airflow. While the disc air jet mill uses the interaction between the high-speed airflow generated by the rotating disc and the material to achieve crushing.

During the crushing process, the various parameters of the air jet mill, such as air flow velocity and pressure, which accurately control the degree and efficiency of crushing of cocoa bean particles. By carefully adjusting these parameters, cocoa powder with uniform and fine particle size can be obtained. Its particle size distribution range can be customized according to the different needs of chocolate production, from the extremely fine powder required for delicate and silky high-end chocolate to the relatively coarse powder suitable for ordinary chocolate, which can be precisely controlled, just like Santa Claus preparing different gifts according to the wishes of children.

2.2 Process advantages

The air jet mill has shown many remarkable process advantages in the production of cocoa powder. Since the pulverization process mainly relies on the interaction between material particles and high-speed airflow, rather than the direct friction of traditional mechanical grinding parts, almost no heat is generated during the pulverization process. This effectively avoids the loss of flavor, destruction of nutrients and color changes caused by heat in cocoa powder.

At the same time, the closed system of the airflow mill greatly reduces the mixing of external impurities. It ensures the purity of cocoa powder and making it taste purer, just like the snowflakes falling on Christmas Eve. In addition, its structural design is relatively simple, easy to clean and maintain. It’s also convenient for rapid switching and cleaning between different product batches. This improves the flexibility and efficiency of production, just like the flexible and changeable tools in the Christmas workshop, which can create different surprises at any time.

III. Market status of air jet mill in cocoa powder and chocolate industry

As consumers’ requirements for chocolate quality continue to increase, air jet mills are used more chocolate industries. At present, the market size of air jet mills around the world is showing a steady growth trend. In Europe and the US, the application ratio of air flow mills is relatively high. Many well-known chocolate brands have adopted air flow milling technology to improve product quality and competitiveness. In Asia, with the rapid rise of the chocolate market, the demand for air flow mills is also increasing dramatically.

IV. Conclusion and Outlook

This study thoroughly explored the application of air jet mills in cocoa powder production and chocolate making. With its unique working principle, the jet mill offers significant advantages in cocoa powder production. The advantages such as no temperature increase, minimal pollution, and easy cleaning. It can produce cocoa powder with a fine and uniform particle size. This high-quality cocoa powder positively impacts the taste, aroma, appearance, and other qualities of chocolate.

The market size of air jet mills in the cocoa powder and chocolate industry continues to expand. The technology has become a key driver of industry development, much like the magical power of the Christmas season. It will bring new vitality to the entire industry.