China is a major producer of lithium battery materials. The pulverization of Lithium materials is a very critical process.

The performance of lithium-ion batteries mainly depends on the performance of the materials used, including positive electrode materials, negative electrode materials, electrolytes, diaphragms, etc. Positive electrode materials, diaphragms, and electrolytes are the core materials of lithium-ion batteries, accounting for 70% of the battery cost. Among them, positive electrode materials have the highest added value, accounting for about 30% of the cost of lithium batteries. The gross profit of different materials ranges from 15% to 70%.

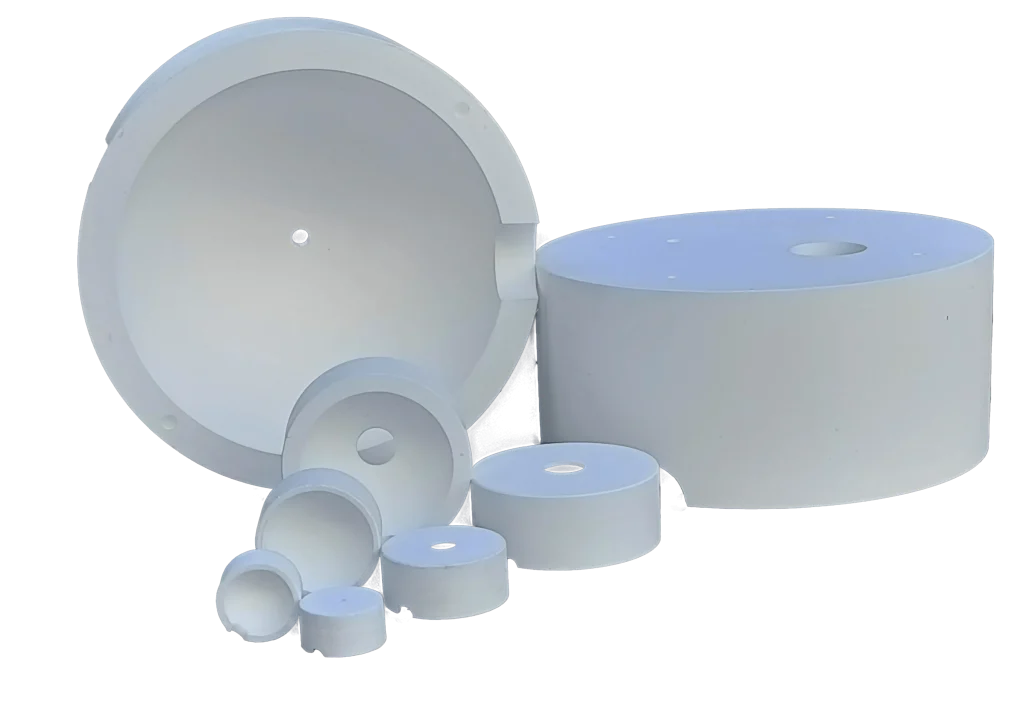

Airflow Pulverization for Positive Electrode Material Processing

The positive electrode materials that have been used in large quantities for lithium batteries are mainly lithium cobalt oxide, lithium nickel oxide, lithium manganese oxide, cobalt nickel manganese oxide (ternary materials), and lithium iron phosphate. Currently, commonly used equipment includes airflow pulverizers, mechanical pulverizers, and sand mills.

Since the development of China’s first fluidized bed airflow pulverizer and the first equipment applied to lithium cobalt oxide materials in 2000, Epic Powder has produced numerous sets of equipment in lithium battery material enterprises across the country .

Airflow Pulverizer for Battery Diaphragm Ceramic Coating Production

As the capacity of lithium-ion batteries increases, the internal energy accumulated increases, causing the internal temperature to rise. In severe cases, short circuits can occur, damaging the battery. Applying high-purity ultrafine alumina on the surface of PP, PE, or multi-layer composite diaphragms can improve the safety of lithium-ion batteries.

The requirements for alumina in lithium battery diaphragm ceramic coatings are:

1. Uniform particle size distribution

2. High purity

3. Consistent crystal structure

The airflow pulverizer from Epic Powder can produce high-purity ultrafine alumina. A company in Shandong has 5 airflow pulverizers from Epic Powder in stable operation, producing ultrafine alumina powder with a purity of 99%.

The fluidized bed airflow pulverizer uses the kinetic energy of high-speed airflow to make the particles collide and rub against each other. It has the characteristics of a continuous production process, large production capacity, and a high degree of automation. It can be used in a variety of fine processing industries, such as electronic materials, chemicals, mining, metal powder, etc.

Its only drawback is the low energy utilization rate. Efforts should be made to reduce energy consumption and increase energy utilization rate. In this way, it will meet the trend of building an energy-saving and environmentally friendly society.

If you are in Lithium Battery industry, welcome to contact us and get to know related machines of Epic Powder airflow pulverizers.