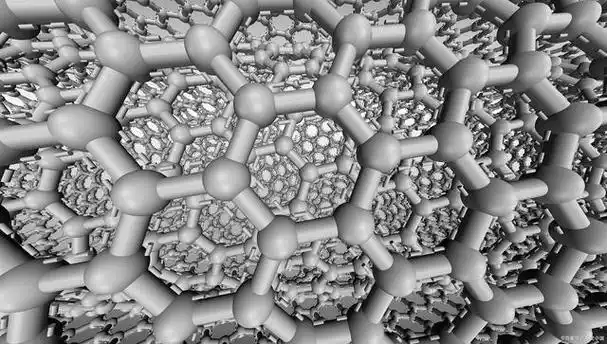

Nano calcium carbonate is a widely used nanomaterial, typically defined as particles with sizes ranging from 1 to 100 nanometers. It boasts excellent biocompatibility and solubility, making it valuable in medicine, food, cosmetics, and other industries. However, the production process of nano calcium carbonate requires high-pressure and high-temperature conditions. This makes the crushing and dispersing of nano-level calcium carbonate a significant challenge. So, nano calcium carbonate dispersing machine has emerged as effective tools for improving production efficiency and product quality.

Characteristics of Nano Calcium Carbonate

Nano calcium carbonate is characterized by its small particle diameter and high specific surface area. Its key attributes include excellent chemical stability, biocompatibility, and highly controllable size and morphology. These properties make it a versatile material for applications in medicine, food, and cosmetics.

To enhance production efficiency, nano calcium carbonate can be processed using a dispersing machine. This equipment utilizes a high-speed rotating shaft to refine nanoparticles. It reduces processing time and costs while achieving more uniform and high-quality particles. As a result, the use of such machinery not only improves product quality but also enhances competitiveness in the market.

Applications of Nano Calcium Carbonate

Nano calcium carbonate is an essential nanomaterial due to its unique physical and chemical properties. It is widely applied in industries such as medicine, food, plastics, and rubber. When used as an additive in various materials, it can enhance hardness, tensile strength, wear resistance, and temperature resistance. Thereby it can increase the material’s durability and production efficiency.

A nano calcium carbonate dispersing machine can quickly and efficiently disperse raw materials. It ensures finer and more uniform particle sizes, which further improves production efficiency and product quality. The applications of nano calcium carbonate are continuously expanding. It is expected to play an increasingly important role in emerging fields such as new energy, environmental protection, and aerospace.

Introduction to Types of Disintegration Machines

Disintegration technology is a crucial step in the preparation of nanomaterials. Currently, common types of disintegration machines include pin mills, cyclone mills, eddy current mills, and multi-rotor dryer mills. Among these, the cyclone mill stands out as an efficient, energy-saving, and environmentally friendly option. It offers advantages such as high disintegration efficiency, simple operation, low wear, and low noise. The equipment disperses large calcium carbonate particles into micron-sized particles through a high-speed rotating disperser, significantly improving production efficiency. Additionally, the nano calcium carbonate disintegrator boasts strong adaptability and can process various types of powder materials. For these reasons, the nano calcium carbonate disintegrator is widely used in both industrial production and laboratory research.

Nano Calcium Carbonate Dispersing Machine

The nano calcium carbonate dispersing machine is essential for improving production efficiency. Its dispersing technology consists of three main stages: pretreatment, filtration, and dispersion.

- Pretreatment: In this stage, raw materials are prepared and mixed to form a homogeneous mixture.

- Filtration: During this stage, impurities and large particles are removed from the mixture through filtration and classification.

- Dispersion: In the final stage, the filtered material is introduced into the dispersing machine, where high-speed centrifugal force breaks the material into smaller particles.

After these three steps, the particle size of nano calcium carbonate is effectively controlled at the nanometer level, improving both production efficiency and product quality.

Choosing the Right Dispersing Machine

The dispersing machine plays a critical role in the production of nano calcium carbonate and can significantly impact production efficiency. When selecting a dispersing machine, several factors should be considered.

- Production Process and Scale: Different models and specifications of dispersing machines should be chosen based on specific production requirements and scales.

- Stability and Reliability: The stability and reliability of the equipment are crucial for ensuring consistent production efficiency and high product quality.

- Maintenance Cost and Difficulty: Consideration should be given to the maintenance costs and complexity of maintaining the equipment.

- Safety and Environmental Performance: The safety and environmental impact of the equipment should also be evaluated.

By considering all these factors and selecting the appropriate dispersing machine, manufacturers can enhance production efficiency, improve product quality, and reduce both production and maintenance costs.

Market Analysis of Nano Calcium Carbonate Dispersing Machine

The nano calcium carbonate dispersing machine is a crucial piece of equipment for improving production efficiency. It has broad application prospects in the domestic market. Currently, the demand for nano calcium carbonate dispersing machines is experiencing steady growth. On one hand, as nano calcium carbonate finds wide applications in industries such as plastics, rubber, coatings, and inks, the demand for dispersing machines is gradually increasing. Nano calcium carbonate offers excellent properties like plasticizing, strengthening, and whitening, which make it widely used to enhance product performance and optimize production processes. On the other hand, as domestic industrialization continues to advance, the demand for automation and intelligent equipment in related industries is also rising. As an advanced piece of production equipment, the nano calcium carbonate dispersing machine offers high efficiency, precise control, and a high degree of automation, which aligns with the market’s growing requirements for equipment performance.

International Market for Nano Calcium Carbonate Dispersing Machines

The international market for nano calcium carbonate dispersing machines is also in a growth phase, particularly in developed countries with a high degree of industrialization. The increasing demand for nano calcium carbonate in these countries has led to the continuous expansion of the market for dispersing machines. Europe and North America have traditionally dominated the production of nano calcium carbonate dispersing machines, but the Asian market, especially in China and Japan, is gradually gaining ground. Among them, China’s market demand is growing rapidly, positioning it as an emerging force in the production of nano calcium carbonate dispersing machines. Additionally, the widespread application of nano calcium carbonate in plastics, rubber, coatings, building materials, and other industries further fuels its market demand, providing ample growth opportunities for the dispersing machine market.

Competitive Landscape

The market for nano calcium carbonate dispersing machines is highly competitive, with several well-established manufacturers both domestically and internationally. Domestically, companies like Qingdao Epic Powder Machinery are making strides, while internationally, companies such as Hosokawa Alpine (Germany) and Union Process (USA) hold a strong market presence. These companies compete by upgrading technology, promoting their brands, and expanding distribution channels. Among them, Qingdao Epic Powder is favored by customers for its comprehensive service system and rich industry experience. As the application of nano calcium carbonate continues to expand across various industries, competition in the market is expected to intensify.