Understanding the relationship between particle size and mesh is essential in powder processing. Whether you’re working with ceramics, minerals, or pharmaceuticals, selecting the right particle size range directly impacts product performance, flowability, and processing efficiency.

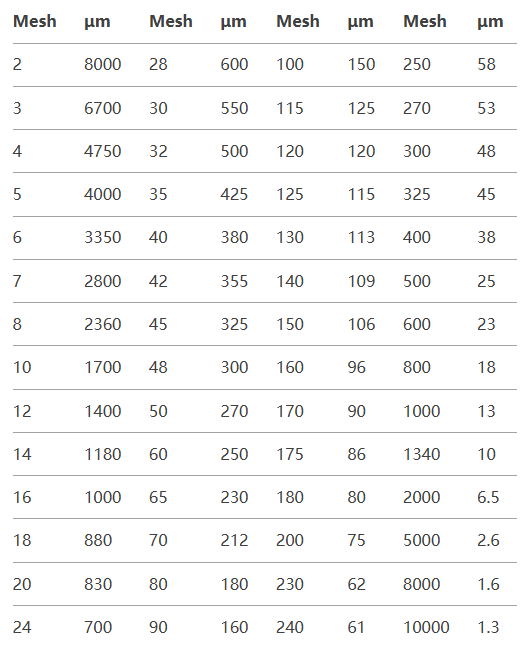

[Generally: Mesh×Aperture (µm)≈15000]

For example: A 100-mesh screen has an aperture of about 150 µm. A 200-mesh screen has an aperture of about 75 µm. A 300-mesh screen has an aperture of about 48 µm. A 500-mesh screen has an aperture of about 30 µm.

Here is a common conversion chart between mesh and particle size. (Remember: 1 mm = 1000 µm.)

If you don’t have the chart handy, use this rough formula:

Mesh × Aperture (µm) ≈ 15000

What Is Particle Size Distribution? What Do D10, D50, and D90 Mean?

Particle size is defined as the spatial size occupied by a particle. The size range can be from sub-nanometer to several thousand microns. The particle’s size is called “grain size,” also known as “particle size” or “diameter.” If a particle behaves like a certain-sized sphere, that diameter is the equivalent particle size. For non-spherical particles, the measured size depends on methods and reference.

So, the particle size is always an equivalent value.

Particle Size Distribution

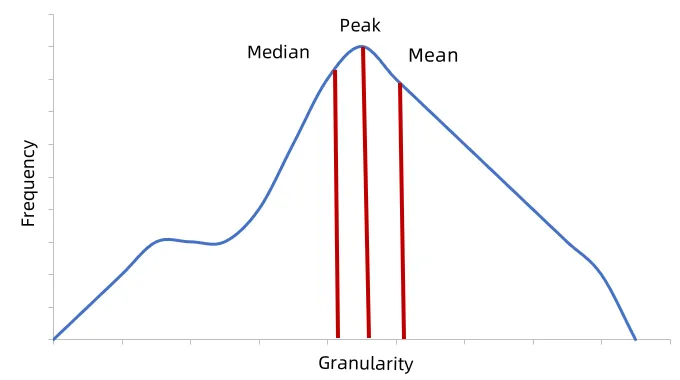

If all particles in a system are the same size, it’s called monodisperse. Otherwise, the system is polydisperse and needs a size distribution chart. Key parameters in a size distribution chart include:

Mean size: The average particle size in the system

Median size: The middle value in the distribution

Peak size: The most frequent particle size

Note: If the chart is asymmetric, these three values won’t be equal.

Figure 1 Particle size distribution: median, peak and average values

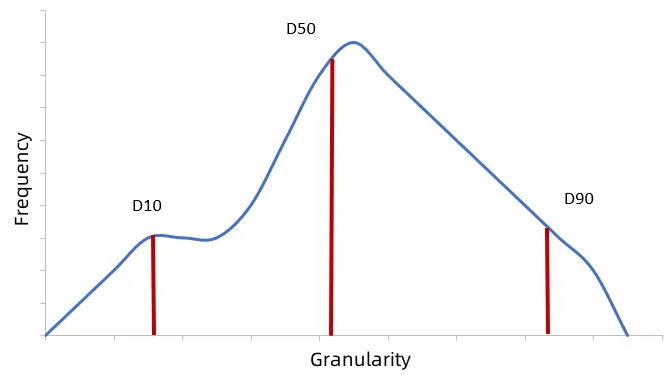

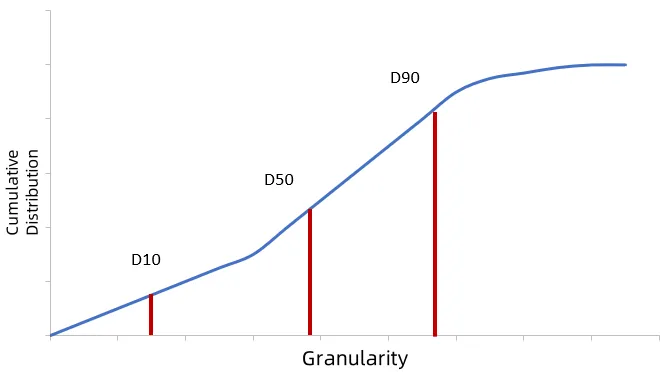

D10: The size at which 10% of particles are smaller

D50: The size at which 50% of particles are smaller

D90: The size at which 90% of particles are smaller Example: If a sample has

If D10 = 3 µm, D50 = 10 µm, D90 = 12 µm That means:

10% of particles are ≤ 3 µm , 50% of particles are ≤ 10 µm, 90% of particles are ≤ 12 µm

Figure 2 Particle size distribution: D10, D50 and D90 diagram

Figure 3 Cumulative distribution: D10, D50 and D90 diagram

Choosing the right mesh and controlling particle size are key to optimizing quality and consistency. With the right strategy and reliable technology, manufacturers can achieve better performance across a wide range of applications. Epic Powder provides expert solutions to help you master particle control and unlock the full potential of your materials.