Working principle of Pharmaceutical spiral jet mill

The spiral jet mill utilizes a high-speed jet of compressed air or gas to grind particles into a fine powder. The particles are fed into the mill through a hopper and are accelerated by the jet stream. The particles collide with each other and with the walls of the mill, resulting in the micronization of the particles.

The Chemical Spiral Jet Mill is a versatile and efficient tool for grinding chemicals. It can be used to grind a wide range of chemical powders, including those that are difficult to grind using other types of mills. Its high-speed jet stream ensures that the chemicals are ground quickly and efficiently, reducing the amount of time and energy required for the grinding process.

Technical Advantages of Spiral Jet Mill

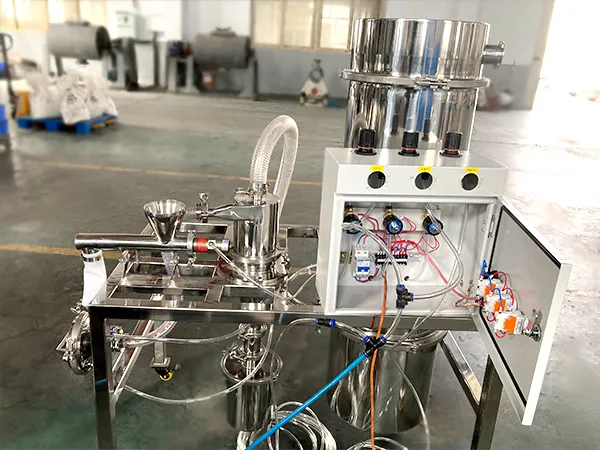

- Without any rotating parts, CNC precision machining, no welding seam, easy to clean.

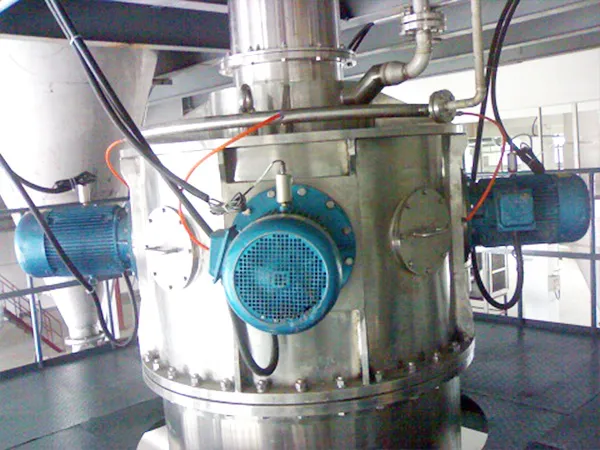

- No medium grinding, the grinding chamber can be protected by stainless steel and wear-resistant ceramics to ensure product purity.

- Low temperature grinding, especially suitable for grinding heat-sensitive, low-melting, sugar-containing and volatile materials.

- The grinding process is extremely short, the crushing efficiency is high, and the over-grinding is less.

- Suitable for grinding, dispersing and depolymerizing, and particle shaping of materials with various hardness.

- The whole system is closed, without dust, low noise and easy to operate.

Spiral Jet Mill technical parameters

| parameter/ Model | MQP01 | MQP02 | MQP03 | MQP06 | MQW10 | MQW15 | MQW20 | MQW30 | MQW40 | MQW60 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Feeding Size(mm) | < 2 | <2 | <5 | <2 | <3 | <3 | <3 | <3 | <5 | <5 | |

| Particle size(D97:μm) | 8~150 | 8~150 | 8~150 | 8~150 | 8~150 | 8~150 | 10~150 | 10~150 | 10~150 | 10~150 | |

| Production Capacity(kg/h) | 5~15 | 5~100 | 10~200 | 20~400 | 50~800 | 150~1500 | 300~2000 | 150~1500 | 300~2000 | ||

| Air consumption(m³/min) | 1 | 2.5 | 3 | 6 | 10 | 15 | 20 | 30 | 40 | 60 | |

| Air pressure(Mpa) | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 |

| Installed power (kw) | 7.5 | 15~20 | 26~37 | 30~37 | 65~85 | 85~100 | 120~142 | 175~200 | 276~310 | 402~427 |